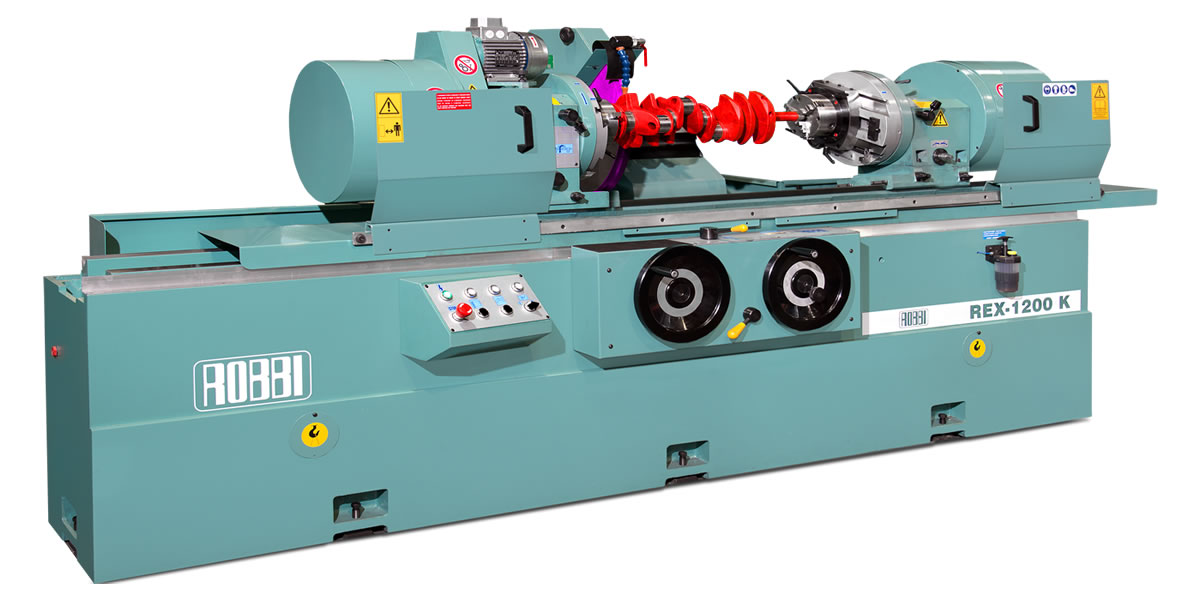

REX Crankshaft Grinders are designed to utilize the most accurate and efficient crankshaft setup system available.

REX Crankshaft Grinders use work heads with 4-way cross slides with an advanced locking system which permits quick centering of the crankshaft.

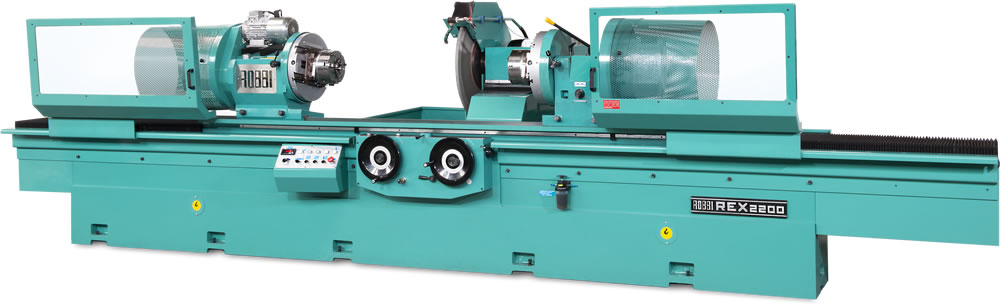

Heavy duty one piece cast iron construction assures you a lifetime of superior accuracy and dependability.

Whatever your crank grinding needs, REX has a model designed to do the job that your customers demand at a price that you can afford.

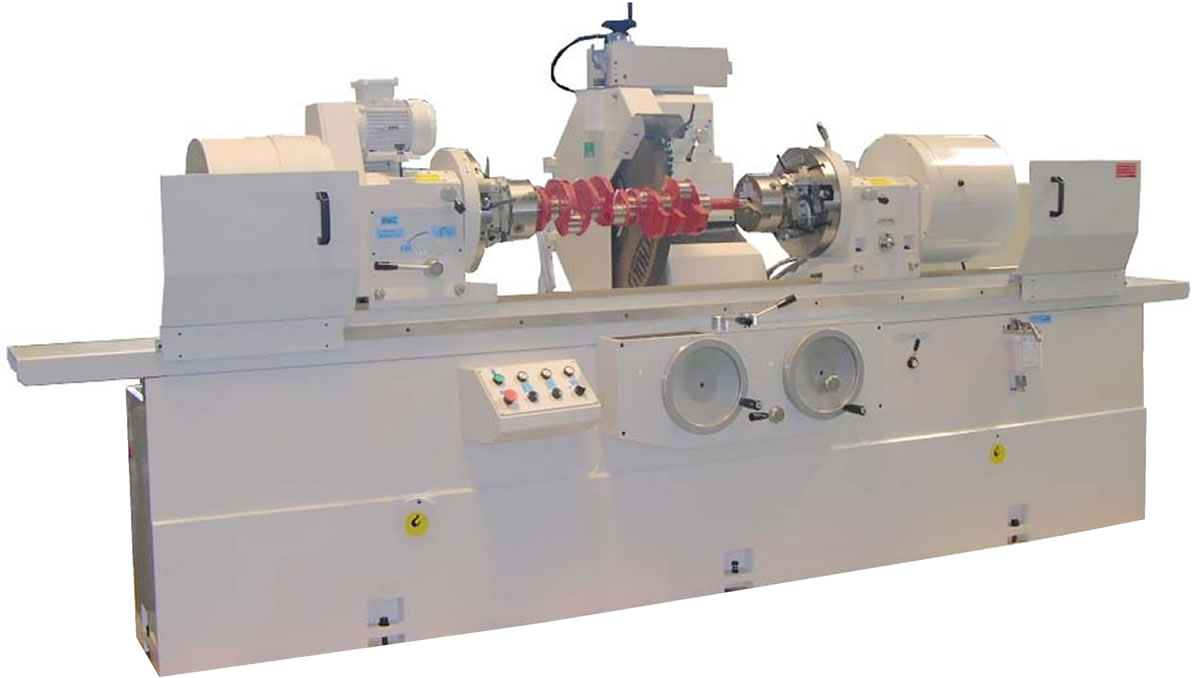

Crankshaft grinding machines

Rex: Hydraulic Crankshaft Grinders

Wheel head

Sideways are coated with antifriction material to obtain free movement and a minimun of wear

Hardened steel spindle, turns in oil bathed fully adjustble precision sleeve bearings

Hydraulic controls

Rapid hydraulic wheelhead traverse and hydraulic table movement increase speed during set-up and grinding

Fine feed controls for both movements assure accuracy

Work Heads

4 way cross slides with advanced locking system permit quick centering of crankshaft. Shiftring is found by a centesimal dial indicator

“O” setting is obtained by shifting the heads against the central stop, which maybe released for possible corrections

Indexed chucks rotate 360 °

Micrometric chuck rotation

Easy change from chucks to centers

Only two keys for all shifting, centering and clamping operations

Workhead

Very large guides