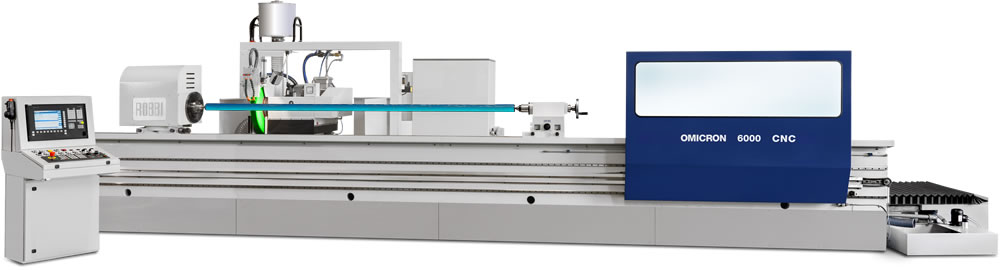

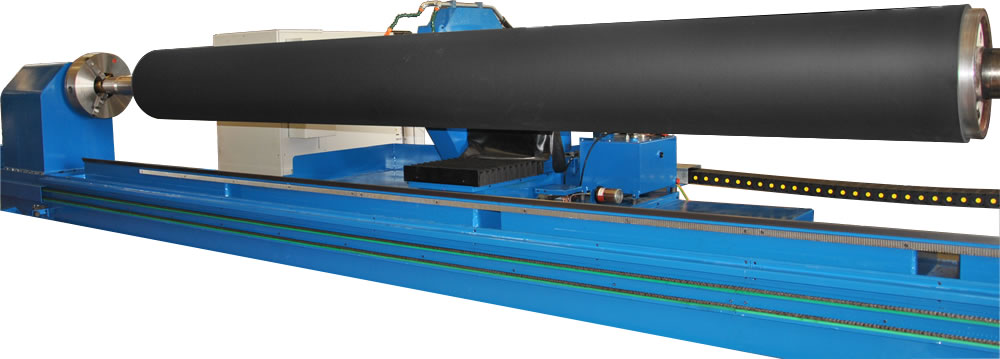

Base

The rigid machine base structure is manufactured from normalised cast iron. A stabilised process ensures the guides will not deform over the life of the machine.

Wheelhead Carriage

The wheelhead carriage is manufactured from normalised cast iron and designed to dampen any grinding vibration and provides optimal rigidity for increased surface finish.

The finished ground face of the wheelhead, is equipped with two high precision, linear guide rails to which 5 pairs of linear guide roller bearings ensure the maximum precision and rigidity of the carriage over the longitudinal travel (Z-axis). The axis travel is carried out via a rack and pinion transmission.

In the transverse axis (X-axis), the carriage runs on linear guide rails with roller guide bearings and travel is controlled by a ballscrew with a 0.1µ, closed loop linear encoder.

High precision, linear roller bearings and guide rails provides minimal friction between moving parts especially at lower feedrates. Optimal linear machine motion across the full machine axes travels.

Wheelhead

The external grinding wheelhead hydrodynamic spindle rotates on anti-friction metal bushes ensuring a high precision surface finish.

Wheel head rotation is undertaken manually, and on request, automatic wheelhead rotation can be offered.

Workhead

A normalised, stabilised cast iron workhead is equipped with a high precision spindle bearings providing maximum rigidity and high performance. The workhead can easily be locked for grinding between dead centres.

On request, the workhead rotation can be controlled with a C Axis to allow the grinding of grooves etc.