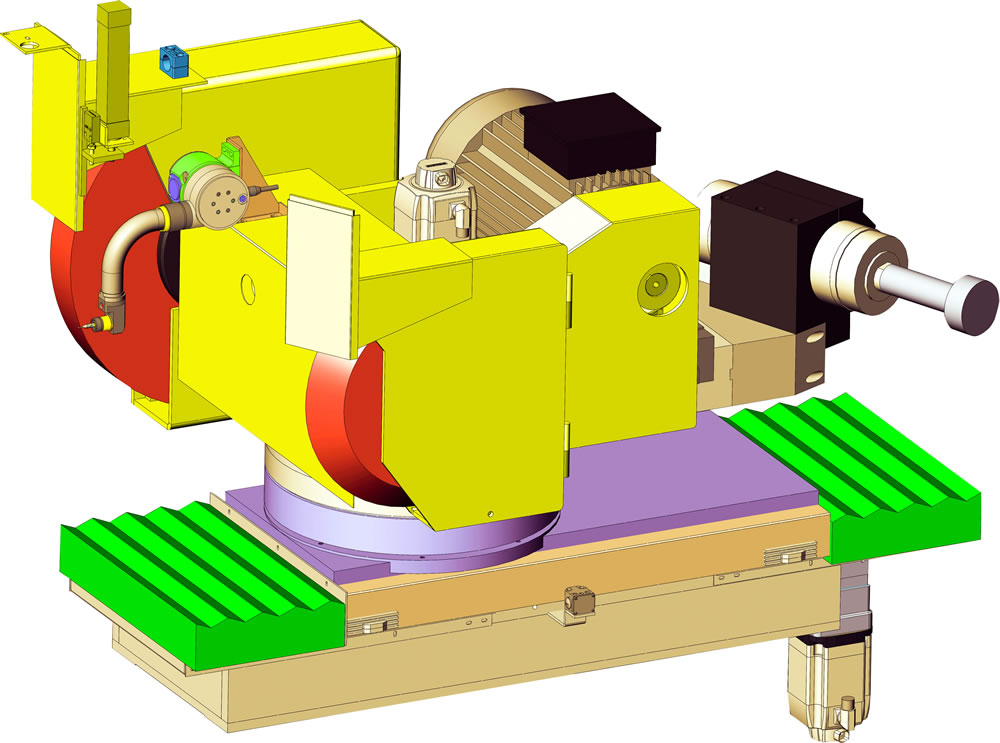

Wheelhead

Customization

Wheelhead can be equipped with a second external grinding wheel, mounted on the right side of the same spindle.

Standard Spindle

Hydrodynamic type, rotates on anti-friction metal bushes, guaranteeing high finish degree.

Rotation iby means of an AC motor.

Transmission by means of pulleys and Poly-V belt.The speed is regulated by inverter

Spindle customization

To answer to more complex processing, the machinescan be realized according to customer’s requirements such as, for example, grinding wheels mounted on two spindles

Some examples of Wheelhead Customization

1 External Grinding Wheel (Standard)

1 External + 1 Internal Grinding Wheels

2 External + 1 Internal Grinding Wheels

La mola destra è più piccola

2 External + 1 Internal Grinding Wheels

Longitudinal movement

The structure is composed of two carriages in normalised cast iron.

The upper carriage where the hydrodynamic spindle is located, has a manual stroke positioning to optimise the use of the grinding wheel

An air flow facilitates the positioning

The lower carriage slides by means of a recirculating ball screw with double preloaded nut, on linear motion guide with roller cage.

The greasing of the guides is timed.

The brushless motor which moves the screw, may be controlled (on request) with a closed loop by the incremental linear encoder, which guarantees a positioning precision on the complete stroke of 0,0001 mm

Wheelhead Rotation

The wheelhead rotates manually 180°, on request, the wheelhead rotation of 180° may be executed :

- manually

- manually with DRO

- index swivel of 2.5°, with Hirth coupling :

- manual

- automatic with brushless motor

- in continue with TORQUE motor